Home > Business field > Air quality business field > Deodorizing Facility

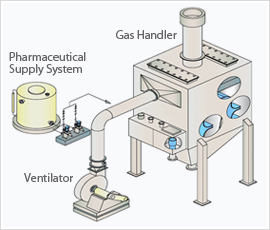

In a Vortex Mix Composite Gas Treatment System, granular air pollutants and malodorous substances are guided into the inflow tube and the guide vane by the wind pressure of an inflow blower without using any separate washing spray or packing facility, and are sprayed through a high speed spray nozzle, when the pollutants are removed by scraping them with deodorizing detergent and vortex mix and by separating and removing the residual fine droplets from the streamlined infringement plate and the gas/liquid separating plate.

| Classification | Treatable air flow rate (CMM) | Specification(W×L×H) | Remark |

|---|---|---|---|

| HEC Ⅱ | 50 | 1200×1200×3000 | Required blast pressure 150mmAα |

| HEC Ⅱ | 100 | 1500×1500×3500 | |

| HEC Ⅱ | 200 | 2000×2000×4000 | |

| HEC Ⅱ | 300 | 2500×2500×4500 |

| Basic Environmental Facilities | Industrial Facilities |

|---|---|

| Composite (offensive odor) gas from foul water or a sewer system | Sticky dust and offensive odor from a textile factory or a chemical plant |

| Composite (offensive odor) gas from foul water/sewage or a waste water treatment plant | Fine dust, paint dust, oil or mist from an iron-making, steel-making or foundry shop |

| Composite (offensive odor) gas from an excreta or a livestock wastewater treatment plant | Composite (offensive odor) gas from a food/medicine manufacturing factory |

| Composite (offensive odor) gas from a waste incineration and sludge treatment facility | Dust and composite (offensive odor) gas from a power generation plant or mechanical equipment factory |