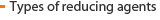

Selective Catalytic Reduction Technology is a technology that enables reduction reaction of nitrogen oxide to take place even with low activation energy by letting the exhaust mixed with the reducing agent pass through the catalytic layer, for which a suitable catalyst is chosen so that the catalyst selectively reacts with nitrogen oxide among the exhaust. It has the highest nitrogen removal efficiency among denitrification technologies, and allows stable operation.

- High and stable NOX removal efficiency (90 % or higher)

- Only a very small amount of NH₃ Slip is generated thanks to optimized amount of reducing agent used

- Conversion rate from high SO₂ concentration to low SO₃ concentration

- A distributor is installed which uniformly distributes exhaust within the reactor.

- Periodic catalyst activity test and report

- The catalyst replacement cost is reduced by using the catalyst again after recycling.

- Design of the optimum reactor through CFD

- High quality technical service

- Easy charging and discharging of the catalyst

- Reducing Agent : Anhydrous Ammonia, Aqueous Ammonia, Urea Solution

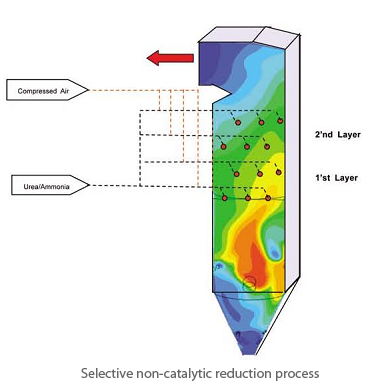

Selective Non-catalytic Reduction Technology is a technology used to remove nitrogen oxide by directly spraying the reducing agent onto the side of the furnace which has an exhaust gas of high temperature range (850 ℃ ~ 1,050 ℃) or into the duct, and the required NOx removal efficiency is expected to be achieved by spraying the reducing agent at an optimal temperature range. Selection of the reducing agent injection nozzle location is an important design factor for performance warranty.

- Inexpensive investment

- It can be used when the boiler is operated with a low load.

- NOx removal efficiency (denitrification efficiency lower than that of SCR)

- Stable maintenance of NOx removal efficiency

- Minimization of NH₃ Slip generation through optimization of the reducing agent used

- Selection of the optimum nozzle location through CFD

- High quality technical service

- Reducing agent : Anhydrous Ammonia, Aqueous Ammonia, Urea Solution