Home > Business field > Air quality business field > VOCs and HAPs removal device

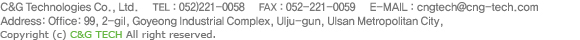

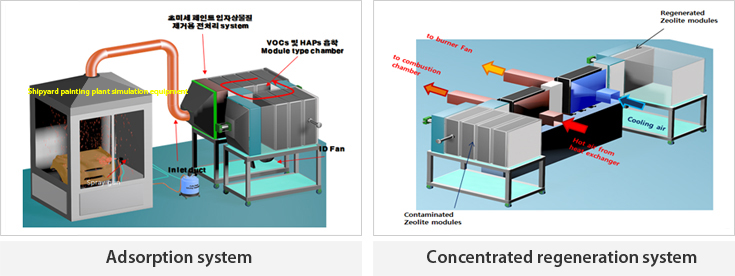

- Compared with the existing filled adsorption equipment, the scale is reduced by 40%.

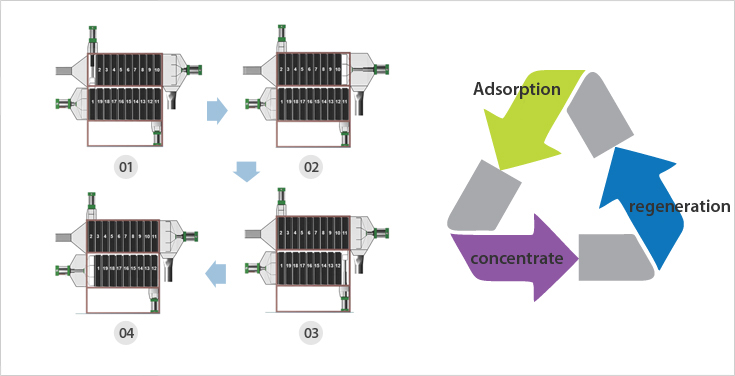

- Easy to move structure to regenerate used sorbent modules.

- Prevents drift (bias current) due to adsorbent load and external vibration, and maintains uniform filling.

- The adsorption function is separated from the regeneration function (used sorbent) and can not reach the minimum explosive limit of VOCs, so the possibility of fire is zero.

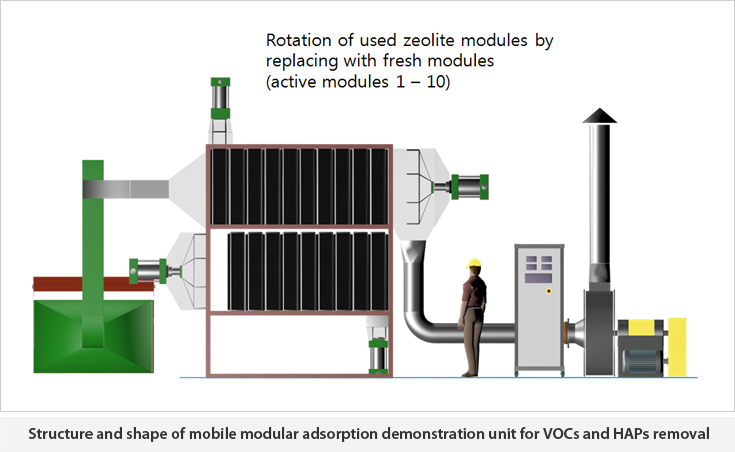

Used to handle VOCs and HAPs emitted due to large-scale coating processes such as shipyards.

VOCs and HAPs are drawn in by inhaling VOCs and HAPs using a mobile modular adsorber, concentrating them through the reagent chamber, and then regenerating their concentrated chambers.

- Appearance & size: Pellet (Ø=3.0 외)

- Colour : Dark brown

- Bulk density : 0.69-0.72g/cc

- Crush strength : > 4.0kg/cm2

- Recomm. operating temp. : 180~240℃

- Upper temp. limit : < 340℃

| Gas | Mechanism |

|---|---|

| TVOCs / Total Volatile Organic Compounds | VOCs + O2 → xCO2 + yH2O |

| THCs / Total Hydro carbons | CxHy + O2 → xCO2 + yH2O |

- Chemical plants, automobile plants

- Manufactory, Sewage / Excreta Treatment Plant

- Harmful gas treatment from semiconductor or flat screen (OLED & LCD / TFT) manufacturing plants

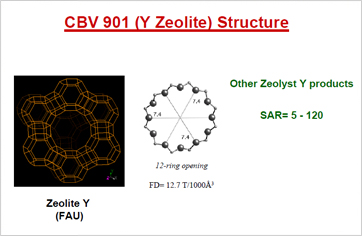

- Shape: spherical, bar

- density : 2.10 - 2.47 g/cm3

- Spherical diameter range : 3mm - 75mm

- 3mm spherical Zeolite surface area : 1.1304cm2

- Spherical features : Small open space

- Shape: powder

- density : 2.10 - 2.47 g/cm3

- Diameter range : 53mm - 300mm

- Specific surface area : 340 - 1,280 m2/g

- Powder characteristics: large specific surface area, adsorption reaction occurs in the entire surface.