Home > Business field > Air quality business field > Blowing facility

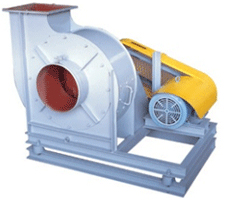

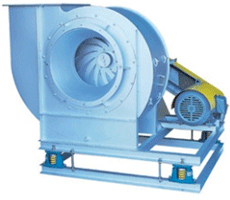

- Being of a large air volume and low static pressure structure, the installation area is smaller than other models.

- It has a low noise and silent operation thanks to the low speed operation resulting from the shape of the impeller.

- It has little change in the wind pressure following the change in the air volume.

- Energy can be efficiently managed in accordance with the location as the air volume and static pressure can be easily adjusted by installing a Vane Damper.

- If the system is operated under the rated static pressure, the power rapidly increases.

- The blade is short and wide: 15mmAq ∼ 70 mmAq (large wind volume, low static pressure)

- It is a forwardly curved blade of which the tip is bent in the direction of rotation.

- The number of blades is bigger than other models (between 42 and 60 blades.

- Air supply and exhaust for an underground parking lot, Ventilation for a machine room, generator room or an electric room

- Air supply and exhaust for firefighting smoke removal, ventilation for a septic tank or a kitchen

- For equipment with imbedded cooling/heating AHU, Ventilation for subway

- Exhaust for other local parts

- It has relatively small noise when operated at high speed.

- It has a particularly strong structure against high static pressure.

- The range of change in the static pressure depending on the change in the air volume is big, and, in the case of straight blade, the range of change in the power is small.

- The selection to be made depending on the required air volume and static pressure is easy as the types are diversified.

- The blade is long and narrow, and of a straight and curved structure: 300 mmAq ∼ 1,500 mmAq (high static pressure).

- It is a backwardly curved blade of which the tip is bent in the opposite direction of rotation.

- The number of blades is relatively small (between 10 and 18 blades).

- Industrial plant비

- Air supply for power generating plant, nuclear facility, and cokes steel-making

- Casting mill, Cupola furnace

- Pneumatic conveyor

- Pollution prevention equipment, incinerator equipment

- Duct collecting equipment, Cleaning equipment, and Water treatment equipment

- It has relatively little noise when operated at high speed.

- It has a strong structure against high static pressure.

- The range of change in the dynamic pressure depending on the change in the air volume is big.

- It can generate a high dynamic pressure (900 mmAq) through pressure rising action by connecting wings in multiple stages

- The width of the casing is narrow as it is a type used for small air volume and high static pressure in which the motor shaft and coupling are directly connected respectively.

- It has a shaft seal device to maintain a high static pressure, and, in the case of multi-stage, has a hydrodynamic high lift structure (guide vane, spin).

- The blade is long and narrow, and of a straight and curved structure: 800 mmAq ∼ 1,500 mmAq (high static pressure).

- It is a backwardly curved blade of which the tip is bent in the opposite direction of rotation.

- A number of wings (multi-stage) can be used to raise the pressure.

- The number of blades is relatively small (between 10 and 18 blades).

- Industrial plant

- Air supply for power generating plant, nuclear facility, and cokes steel-making

- Casting mill, Cupola furnace

- Pneumatic conveyor

- Incinerator equipment

- Water treatment equipment (for an aeration tank)