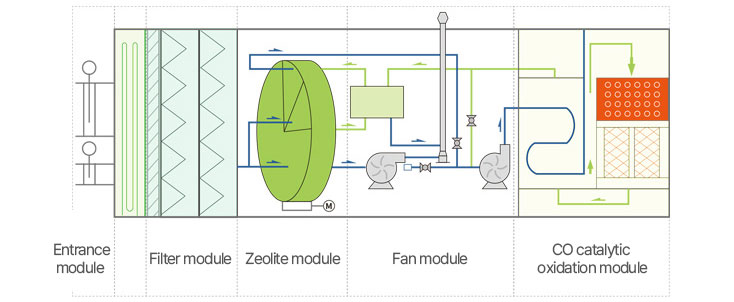

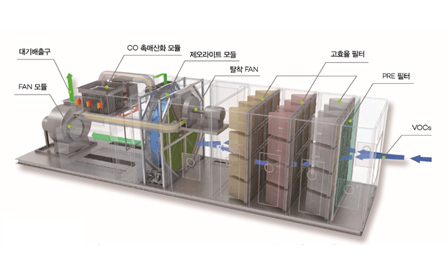

All-in-one VOCs Adsorption for removal and Concentration regeneration device

Introduction of the facility

Distinction

- Apply modular design

- Easy to disassemble and assemble

- Assembly with different functional modules

- Select and assemble each functional module according to the field situation

Process

Adsorption/Concentration technology combination system

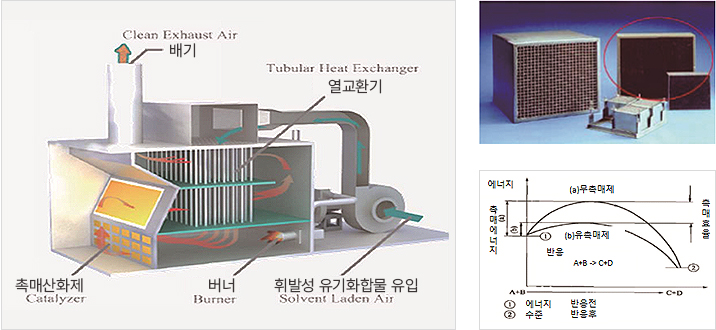

VOCs adsorption concentration rotary ROTOR and catalytic oxidation CO combined VOCs management system

Distinction

- Oxidation temperature 300°C

- Using tube or plate heat exchanger, heat efficiency 65%

- Processing efficiency 90% ~ 99%

- Land area is relatively small

- Maximum internal temperature ~500°C

- Suitable for intermittent operation

- Cannot process organic substances such as sulfur and halogen

VOCs adsorption concentration turntable

Distinction

- Excellent adsorption performance

- Adsorption efficiency 90 ~ 99%

- Available in various shapes

Catalytic oxidation

Distinction

- The catalytic action reduces fuel consumption by lowering the activation energy of the reaction during the catalytic combustion process.

- Catalytic oxidation heats the exhaust gas to 300℃ and completely decomposes organic matter into CO₂ and H2O through the catalytic action.

- Using precious metal (Pt, Pd) catalysts, energy consumption is reduced due to low reaction temperature, and the purification efficiency is over 95%, which reduces investment costs.

- Using a ceramic carrier stabilized at high temperatures, the catalyst does not sinter, and maintains a large specific surface area, mechanical strength, and stability against high heat.

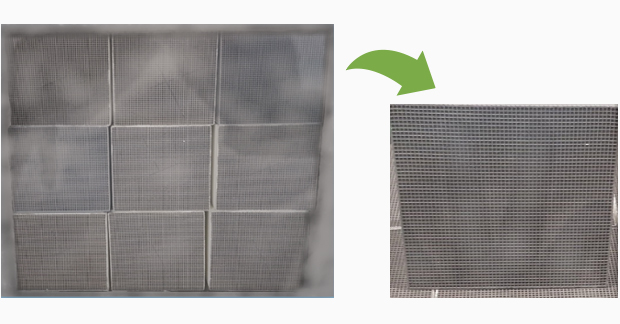

Technical Advantages of catalysts

Distinction

- 40~50% weight reduction compared to existing products

- 30% increase in surface area due to high porosity

- Reliable low-temperature and high-temperature catalytic activity

- Increased diameter, increased treatment area

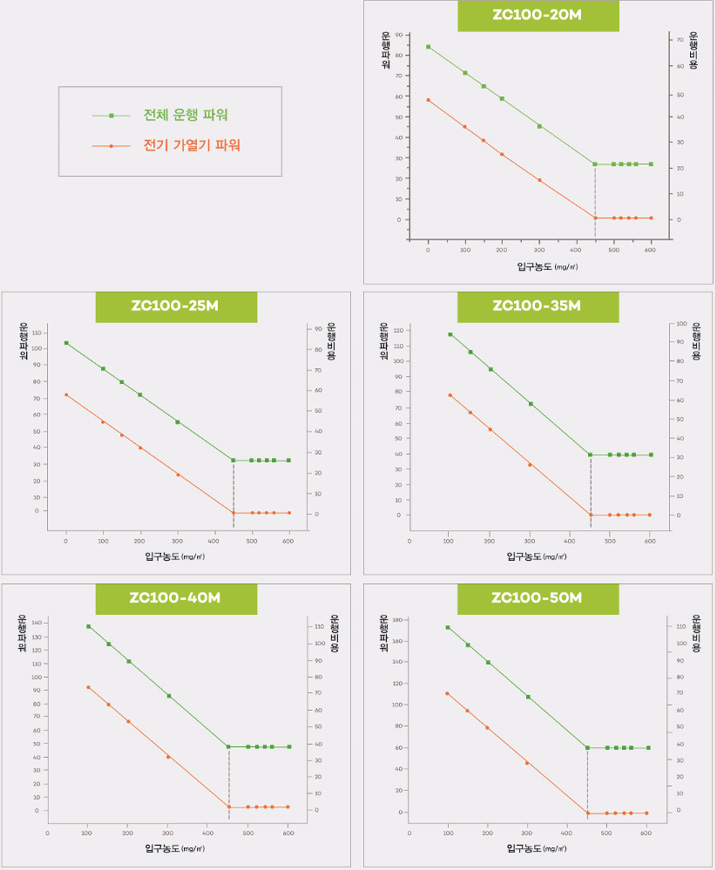

Operating costs and energy consumption

Test report

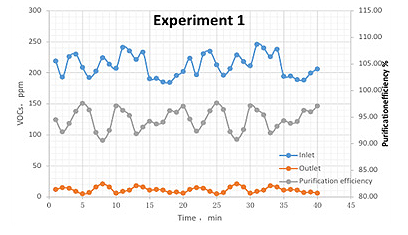

1. Adsorption test

시험 항목 및 조건

| VOCs유형 | 풍량 m³/h | 농도 ppm | 출구농도 | |

|---|---|---|---|---|

| 실험 1 | 자일렌 | 20000 | 300-400 | < 30 |

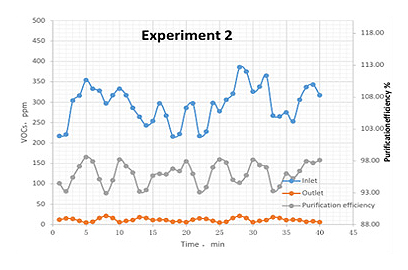

| 실험 2 | 자일렌-아텔아세테이트 (2:1) | 20000 | 300-400 | < 30 |

Result

As can be seen in the exhaust gas concentration graph, the xylene inlet concentration is 190~330ppm, the exhaust gas emission concentration is 5~10ppm, and the overall equipment efficiency is over 92%.

2. Desorption test

시험 항목 및 조건

| VOCs유형 | 풍량 m³/h | 농도 ppm | 탈착풍량 Nm³/h | 분자 로타유형 | |

|---|---|---|---|---|---|

| 실험 1 | 자일렌 | 20000 | 200-330 | 2500 | 2350-40-III |

| 실험 2 | 자일렌-아텔아세테이트 (2:1) | 20000 | 200-400 | 2500 |

Result

As can be seen in the exhaust gas concentration graph (xylene: ethyl acetate = 2:1), the inlet concentration is 200 to 400 ppm, the exhaust gas outlet concentration is 5 to 20 ppm, and the overall efficiency of the equipment is over 93%.