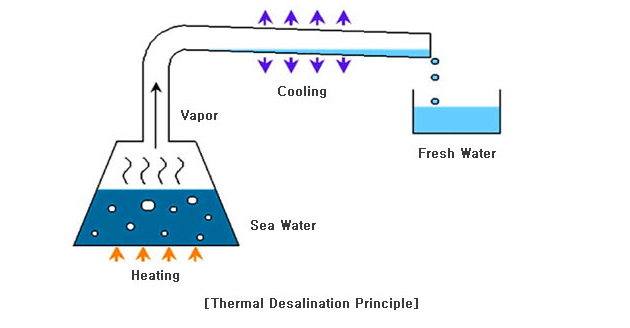

Evaporation system is a method which uses the water circulation phenomenon which takes place in nature on the earth. That is to say, it uses, in an engineering aspect, the phenomenon that the vapor evaporated from sea surface becomes cloud being condensed in the low temperature atmosphere of the top part of the elevating troposphere, and falls down to the earth surface of sea surface again in the form of rain. Though it has advantages that its capacity is big, there are many track records, and the purity of the water produced is high, it also has a weak point that the energy consumption is big.

Fresh water is separated from sea water using the nature that, when sea water is evaporated, water which is a solvent evaporates, and salt which is a solute remains. It is divided into Multi Stage Flash Distillation, Multi Effect Distillation, and Vapor Compression Distillation in accordance with the vapor evaporation recycling method.

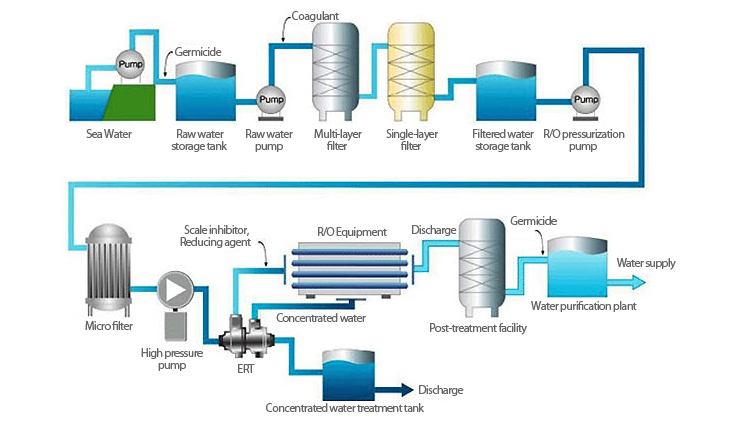

Reverse osmosis is a method which uses pressure energy. It separates only fresh water by pressurizing sea water to push it against a reverse osmosis membrane which allows water to pass through it but almost no solute (ionic material). The water produced by a reverse osmosis membrane contains almost no ionic material.

- Optimization of high efficiency pump and concentrated water energy recovery device for power cost reduction

- Speed control by an inverter (VFD)

- Increase in the quantity of elements per vessel ( 1 ~ 7 Element/Vessel)

- More efficient RO unit arrangement

- Simplification of the water intake facility using coolant of the power generating plant

- Development of advanced pre-treatment technology

- Diversification of the pre-treatment methods using UF/MF membranes achieved thanks to advancement in the membrane technology

- Increase in the throughput and improvement in the salt removal rate through membrane performance improvement

- Minimization of production cost and operation cost achieved by fresh water plant built by combining multi-stage flash evaporation method and reverse osmosis method

- The production cost and operation cost of the reverse osmosis plant within the Hybrid system is reduced by about 10 to 15 % from that of the plant using single reverse osmosis method.

- Maximization of Flux for maximization of recovery rate

- Minimization of fouling through improvement in membrane

- Minimization of use of chemicals