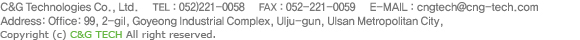

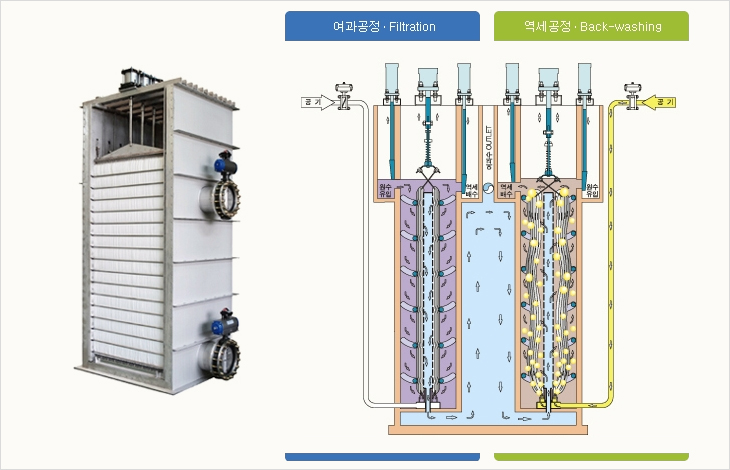

It is a Gravity Flow Fiber (GFF) filter. Gravitational filtration is done using the water level difference of about 30 cm by seating a bundle of nonwoven fiber filters with fixed bottoms, squeezing them down to the perforated panel until the thickness of the filter layer is reduced to 2 to 3 cm, and loosening the filter when the water level reaches the set value, after which the filter is back washed by the strong shearing force generated as a result of the textile movement when an elevating impulsive force water current is formed by the sprayed back washing air. It is also called a pumpless filter as no back washing pump is required because back washing water is supplied as elevating water current when two or more GFFs are installed.

| DESCRIPTION | SS Density | NO CHEMICAL DOSING | CHEMICAL DOSING PAC(30PPM) | ||||

|---|---|---|---|---|---|---|---|

| RAW WATER |

FILTERED WATER |

EFFICIENCY (%) |

RAW WATER |

FILTERED WATER |

EFFICIENCY (%) |

||

| SS | Normal condition SS 10 or lower |

5.9 (3.7~90.) |

0.7 (0.4~1.2) |

87.5 (82.4~93.0) |

3.3 (2.5~3.8) |

0.33 (0.3~0.4) |

89.9 (87.5~92.1) |

| Whole | 14.6 (3.7~34.8) |

1.3(0.4~2.2) | 98.7 (82.4~95.0) |

11.2 (2.5~22.5) |

0.6 (0.3~0.8) |

93.2 (87.5~96.4) |

|

| BOD | Normal condition SS 10 or lower |

10.6 (5.6~20.1) |

2.3 (1.2~4.4) |

79.9 (58.9~88.1) |

12.3 (10.4~13.3) |

1.2 (0.8~1.5) |

90.3 (87.5~93.9) |

| Whole | 21.3 (5.6~40.9) |

3.9 (1.2~10.2) |

80.2 (58.9~93.0) |

16.6 (10.4~22.1) |

1.4 (0.8~1.9) |

91.1 (87.5~93.9) |

|

| T-P | Normal condition SS 10 or lower |

1.6 (1.4~1.7) |

1.5 (1.4~1.6) |

6.0 (0.9~12.0) |

1.2 (1.2~1.3) |

0.31 (0.22~0.41) |

75.3 (66.9~91.5) |

| Whole | 1.7 (1.4~2.3) |

1.5 (1.2~1.8) |

12.2 (0.9~28.4) |

1.6 (1.2~2.1) |

0.4 (0.22~0.75) |

72.2 (64.0~81.5) |

|

As to medium and high concentration than the normal condition (SS 10 or lower), the test was conducted by artificially adjusting the SS. / Whole: Sum of the low (normal), medium and high concentrations

If the SS concentration is low, direct filtration can be done after coagulation (skipping precipitation)

- No need of filtration pump: Gravitational filtration shall be conducted using the water level difference of about 30 cm by squeezing the filter down to the perforated panel until the thickness of the filter layer is reduced to 2 to 3 cm.

- No need of back washing pump: The water in the filtration tank is automatically supplied through the overflow resulting from the rise in the water level when the back washing air is spurted (when two filters are installed).

- Minimization of filtering device: As it uses a rectangle plate type filtering plate, it has a wider filtering layer in the same space than that of a cylindrical or cylindrical/plate type filtering plate.

- High efficiency filtration: Deep bed filtering effect is achieved by non-woven floating filter layer which is thicker than woven fixed filter layer.

- High efficiency back washing function: Attachment of salts and proliferation of biological slime can be prevented as violently moving back washing is possible thanks to nonwoven floating filter layer.

- Function to allow maintenance during operation: The system can be designed to prevent adulteration of raw water during adsorption and desorption by a unit filter through operation of the check valve (an option).

- The performance may differ depending on the grain size and viscosity, and this specification may be changed without notice for performance improvement.

- Floating solids with grain size smaller than 5 ㎛ can be also treated by strengthening the pressing force, using microfilament, reducing the throughput, and adding a coagulant.

- Design height of the machine room: H + 1 m or higher

※ NCD : No Chemical Dosing / CD : Chemical Dosing

| CAP(㎥/HR) | UNIT FILTER |

SIZE(W×FH×/H×D) | FILTER MODULE L(M)×EA |

|

|---|---|---|---|---|

| NCD | CD | |||

| 150N(6.25) | 75C(3.125) | A | 610×1350/1850×250 | 1.39×68 |

| 300N(12.5) | 150C(6.25) | B | 1220×1350/1850×250 | 1.35×136 |

| 600N(25.0) | 300C(12.5) | 2C | 1525×2250/2950×250 | 1.35×272 |

| 1000N(41.7) | 500C(20.8) | 4D | 1525×3600/4300×250 | 3.64×170 |

| 2000N(83.3) | 1000C | 2D | 1525×1800/2500×1000 | 3.67×340 |

| 4000N(166.7) | 2000C(83.3) | 4D | 1525×3600/4300×1000 | 3.64×680 |

| 6000N(250.0) | 3000C(125.0) | 6D | 1525×3600/4300×1000 | 3.64×1020 |

| 8000N(333.3) | 4000C(166.7) | 8D | 1525×3600/4300×2000 | 3.64×1360 |

| 10000N(416.7) | 5000C | 10D | 1525×3600/4300×2500 | 3.64×1700 |

| 12000N(500.0) | 6000C(250.0) | 12D | 1525×3600/4300×3300 | 3.64×2040 |

- UNIT FILTER TYPE = > A : 650×1350, B : 1220×1350, C : 1525×2250, D : 1525×3600

* Above is the size for which civil engineering structure, pipe, etc. are not considered and can be adjusted depending on the depth of the tank, etc.

- For improvement in the quality of water discharged, and filtration of recycled water

- For filtration of drinking water in a mineral water company or a water purification plant

- For pre-filtration in a high level processing, separation by membrane, etc.

- For filtration required for maintenance of cleanliness in a swimming pool or an aquarium

- For filtration of green algae/red algae in a water intake station, fish farm, etc.

- For filtration of cooling/circulating water, agricultural, and industrial water